-In our Turbocharger Reman department, we are equipped with state-of-the-art testing devices. We perform reman operations for turbochargers of passenger vehicles, heavy commercial vehicles, construction machinery, marine engines, and industrial motors.

Following the conscious remanufacturing performed by our expert team, final testing is carried out using high-tech test equipment approved by turbocharger manufacturers.

The Gatetest-12 test equipment, manufactured by Redat a world leader in its field and approved by turbocharger manufacturers enables precise calibration of airflow in variable geometry turbochargers. It performs minimum, medium, and maximum flow rate measurements, actuator testing and programming, as well as pneumatic and vacuum actuator testing and adjustments, all in accordance with OEM specifications.

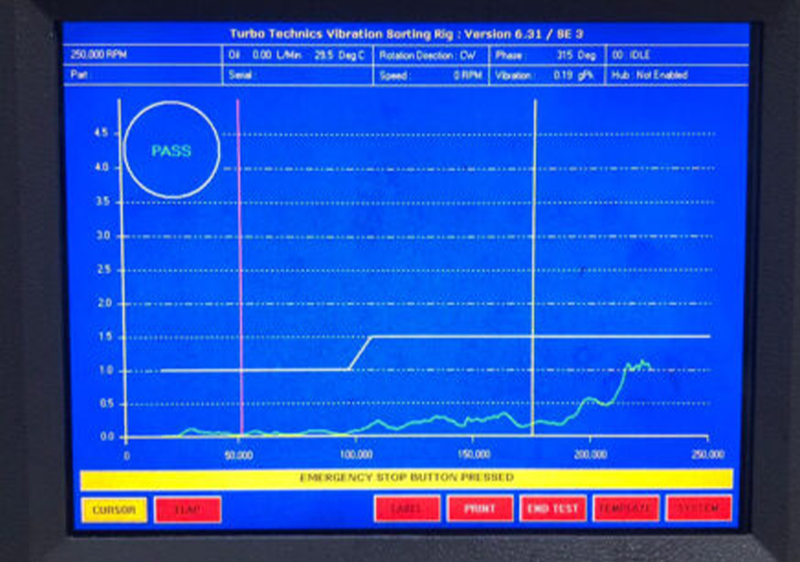

The VSR 400 high-speed noise balancing machine, approved by turbocharger manufacturers and used on their production lines, is a high-precision device used to rebalance turbochargers after reman. It simulates real engine operating conditions, assisting in accurate testing and balancing with high precision.

The VSR 400 turbo balancing machine is specially designed for dynamic and static balancing of turbocharger rotors. It performs fast, precise, and stable measurements at high speeds (up to 300,000 rpm) to ensure accurate turbocharger balancing.

We stock a wide range of revised and new turbocharger products for all vehicle categories to meet the needs and demands of our customers.

Turbochargers for all brands and models of cars, construction machinery, marine vessels, tractors, trucks, and light commercial vehicles are diagnosed by our professional team using original testing equipment. Faulty components are identified and replaced to ensure complete refurbishment.